Nanoelectronics & Nanoenergetics Materials

Prof. Nacer Badi, Project Leader

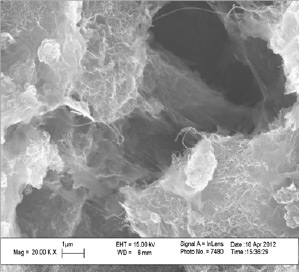

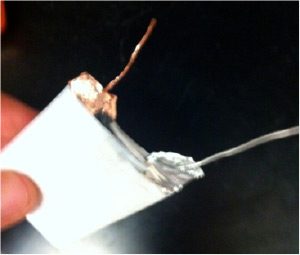

Storage of electrical energy remains the weak link in achieving wider use of highly intermittent renewable energy sources such as wind and solar energy. NNL Group focuses on nanodielectric materials and nanostructured carbon electrodes, both, for energy storage solutions. The research team is building these materials at the nanoscale level so that new classes of nanomaterials and devices could emerge to power our daily life. The project goal is to achieve: 1) high permittivity aluminum-alumina (Al-Al2O3) core-shell based artificial nanodielectrics using green chemistry processes. Resulting capacitance value in the range of 10–25 nF/in2 is in par with commercially available capacitor devices but with the added structural flexibility and cost-saving to the end user 2) carbon nanostructures (CNS) based components for electrochemical batteries and ultra-capacitors technologies that are suitable for all types of electrical vehicles (HEVs, PHEVs, BEVs). We have already identified and tested successful production of CNS material, their applicability, and characterization as well as cost analysis in comparison to currently available activated carbon counterpart. Tested CNS consists of commercially purchased graphene, carbon nanotubes (CNT), and carbon fibers. The electrochemical analysis of first fabricated battery prototypes shows excellent capacity in the range of 100–250 mAh/g with energy efficiency above 80%. To further enhance the above research efforts and cut down on fabrication expenses, we have setup and used commercially available COMSOL software which allows multi-physics coupling modeling and simulation capabilities.

With respect to electrochemical devices, we will further our investigation into CNS material and fabrication methodologies which can facilitate the goal of creating a large-scale energy system that is not only cost effective, but also easily replicable and amenable to high volume manufacturing. The next step is to manufacture hybrid CNS-Silicon by mechanical means. Ball milling process seems a viable approach for mass production of cost effective anode materials for lithium ion batteries. This can result in a cost effective process with strong potential to launch in an industrial set up. I believe this technology will boost the performance and stability of the lithium ion batteries while driving the price of actual anode materials down (from $20–$40/Kg to about $5/Kg).

Due to the nature of CNS blend, it exhibits large surface area that can be consolidated under different conditions to reach desired levels of porosity (nano–meso scale), from fully dense materials to highly porous membranes. In parallel, we envision a computational effort in collaboration with Texas A&M University and an empirical study that could be useful to the community in general for achieving performance closer to theoretical limits in CNT based electrochemical energy storage devices. The ultimate goal is to fabricate electrode/electrolyte materials that will enable both batteries and ultra-capacitors to meet power requirement for electrification of the transportation system.

Publications

N. Badi, A. R. Erra, F. C. Robles Hernandez, A. O. Okonkwo, K. Martirosyan, and M. Hobosyan, “Low-cost carbon-silicon nanocomposite anodes for lithium ion batteries” Nanoscale Research Letters, 2014,9:360.

F. Chouit, O. Guellati, S. Boukhezar, A.Harat, M. Guerioune, and N. Badi, “Synthesis and Characterization of HDPE/N-MWNTs Nanocomposite Films”, Nanoscale Research Letters, 2014, 9:288.

N. Badi, S. Vijayaraghavan, A. Bensaoula, A. Tempez, C. Tauziède, P. Chapon, “P2IMS depth profile analysis of high temperature boron oxynitride dielectric films” Applied Surface Science, 292, 1 (2014).

N. Ansari, S. Khasim, A. Parveen, O. Al-Hartomy, Z. Khattari, N. Badi, and A. S.Roy “Synthesis, Characterization, Dielectric and Rectification Properties of PANI/Nd2O3:Al2O3 Nanocomposites”, Polymer for Adv Tech., (2016).

R. Ebrahim, M. Kumar, N. Badi, N. Wu, and A. Ignatiev, “Filamentary bipolar EPIR switching in amorphous silicon”, J. Appl. Phys. 2014 (submitted).