Space Materials Science

Prof. Alex Ignatiev, Project Leader

The Wake Shield Facility — Epitaxial Growth in Space Ultra-Vacuum

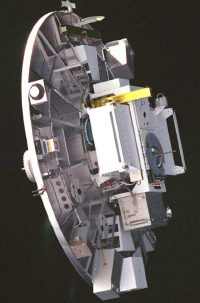

The utilization of the vacuum of space for thin film materials development was pioneered by the Center through the Wake Shield Facility (WSF) program. The Wake Shield Facility is a 4 m diameter disc-shaped free flying platform designed to generate an ultra-vacuum in low earth orbit space, and to utilize that ultra-vacuum for the fabrication of thin film materials by epitaxial growth. The Wake Shield Facility was the first NASA primary payload created and flown by a small, dedicated team with focus on a commercial approach to flight hardware development. This resulted in highly cost-effective and time-effective flight hardware development and flight.

The Wake Shield Facility was transported to orbit by the Shuttle in its payload bay mounted on a specifically designed cross-bay carrier. The carrier not only restrained the WSF in the payload bay, but also protected the central epitaxial growth region of the wake side from pre-launch payload processing environments, and payload bay launch environments through the incorporation of an integral vacuum chamber. The WSF was deployed from the Shuttle payload bay by the Shuttle’s remote manipulator system (RMS or ‘arm’). In order to eliminate contamination of the WSF by Orbiter thrusting during the separation maneuver, the WSF moved away for the Orbiter under its own small nitrogen gas thruster, and moved to ~30 nmi separation behind the Orbiter for the wake vacuum thin film growths.

The thin film growth apparatus on the WSF included 8 source cells (small furnaces) for the evaporation of elemental atoms for molecular beam epitaxy (MBE) thin film growth, and two gas nozzles for the effusion of organometallic gaseous species for chemical beam epitaxy (CBE) thin film growth. The MBE/CBE apparatus allowed for growths on seven separate substrate wafers, with the growths supported by total pressure gauge and a mass spectrometer measurements of the residual vacuum environment at the growth region (center of the disk), In addition to the thin film growth apparatus, the WSF was instrumented with additional mass spectrometers and total pressure gauges for the characterization of the wake vacuum environment.

Epitaxial films in the GaAs III-V family of semiconductors were grown in space ultra-vacuum with the aim of minimizing/eliminating contaminations seen in terrestrial vacuum chamber growths. Results fully validated contamination reduction in space ultra vacuum with direct growths of nearly carbon-free AlGaAs films.

Solar Cells on the Moon

Energy is fundamental to nearly everything that humans would like to do in space, whether it is science, commercial development, or human exploration. If indigenous energy sources can be developed using in-situ resopurces, a wider range of possibilities emerge for subsequent space development.

It should be noted that the Moon (other planetary moons and asteroids) has unique conditions that allow for in-situ energy generation. These entities have essentially no atmosphere — i.e. a high vacuum surface environment, and they contain most all elements required for the fabrication of solar cells — e.g., semiconductors, metals, and optical coating materials. These conditions allow for the possibility of fabricating thin film solar cells DIRECTLY on the surface of a moon (or asteroid) given the appropriate tools that can support thin film solar cell fabrication.

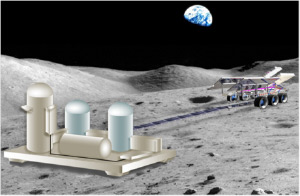

The lunar solar cell fabrication approach is comprised of a robotic vehicle — the Cell Paver and a Regolith Processor. The ultra-high vacuum (1 x 10-10 Torr) environment of the lunar surface is ideally situated for vapor deposition of the thin film structure required to make silicon solar cells by the Cell Paver. The lunar regolith (the fine surface dust prevalent on the Moon to depths of from 1–20 meters) can be processed by the Regolith Processor to extract silicon and metals needed to fabricate the thin film solar cells, and can also be solar-thermally melted to form a nano-smooth high resistivity glass to act as a substrate for cell growth. A metal bottom contact layer can then be sequentially solar-thermally evaporated onto the lunar glass substrate followed by evaporation of p- and n-doped silicon to form the solar cell. Such a thin film deposition on glass results in microcrystalline silicon which, if the grain size is of the order of 1 micron or more can yield an efficiency of ~5% to 10%.

Continuous fabrication of thin film solar cells on the surface of the Moon is a new approach to energy generation on the Moon to assure an energy-rich environment for lunar and cis-lunar space.

Publications

A. Ignatiev, “Industry Impact of Thin Film Electronic Materials Growth in Space”, Proc. 4th Internat’l Conference on Commercial Use of Space, pp231 (Gordon & Breach, Montreaux) 1992.

A. Ignatiev and A. Freundlich, “Solar Cells for Lunar Applications by Vacuum Evaporation of Lunar Regolith Materials”, Proc. 43 Congress of Internat’l Astro. Federation, IAA 92-0158 (1992).

A. Ignatiev, “The Wake Shield Facility and Space-Based Thin Film Science and Technology”, Earth Space Review, 4, 10 (1995).

A. Ignatiev, C. Horton, M. Sterling, R. Sega, A. Bensaoula, A. Freundlich and S. Pei, “Advanced II-V Materials Processing in the Vacuum of Space”, Proc. IEEE GaAs IC Conference, 94CH34488, 13 (1994).

A. Ignatiev, M. Sterling, C. Horton, A. Freundlich, S. Pei, and R. Hill, “Thin Film Microelectronics Materials Production in the Vacuum of Space” AIP Conf. Proc. 387, 685 (1997).

G. Neu, M. Tessiere, A. Freundlich, C. Horton, A. Ignatiev, “Donor acceptor pair spectroscopy of GaAs grown is space ultra vacuum”, Applied Physics Letters, 74, 3341 (1999)

A. Freundlich, T. Kubricht and A. Ignatiev, “Lunar Regolith Thin Films: Vacuum Evaporation and Properties”, AIP Proceeding 420, p660 (1998).

A. Ignatiev, “Advanced Thin Film Materials Processing in the Ultra-vacuum of Space”, Acta Astronautica, 48, 115 (2001).

A. Freundlich, C. Horton, M. Vilela, M. Sterling, A. Ignatiev, G. Neu, and M. Teisseire, “Photoluminescence of GaAS grown by metallorganic molecular beam epitaxy in space Ultra-vacuum”, J. Crystal Growth, 209, 435 (2000).

J. A. Strozier, M. Sterling, J. A. Schultz and A. Ignatiev, “Wake vacuum measurement and analysis for the wake shield facility free flying platform”, Vacuum, 64, 119 (2001).

Michael B. Duke, Alex Ignatiev, Alex Freundlich, Sanders Rosenberg, and Darby Makel, “Silicon PV Cell Production on the Moon”, J. Aerospace Eng. 14, 77 (2001)

Alexandre Freundlich, Alex Ignatiev, Charles Horton, Mike Duke, Peter Curreri, and Laurent Sibille, “Manufacture of Solar Cells on the Moon”, IEEE Photovoltiaic Specialists Conf, 31, 794 (2005).

C. Horton, C. Gramajo, A. Alemu, L. Williams, A. Ignatiev and A. Freundlich “First Demonstration of Photovoltaic Diodes on Lunar Regolith Based Substrate”, Acta Astronautica, 56, 537 (2005).

A. Ignatiev, K. Heiss and P. van Susante, “ISRU-based development of a lunar water astroparticle observatory”, Acta Astronautica, 61, 496 (2007)

Alex Ignatiev, Alexandre Freundlich. Klaus Heiss and Christopher Vizas, “Solar Cell Fabrication on the Moon from Lunar Resources”, Lunar Settlements, ed; H. Benaroya (CRC Press, 2009).